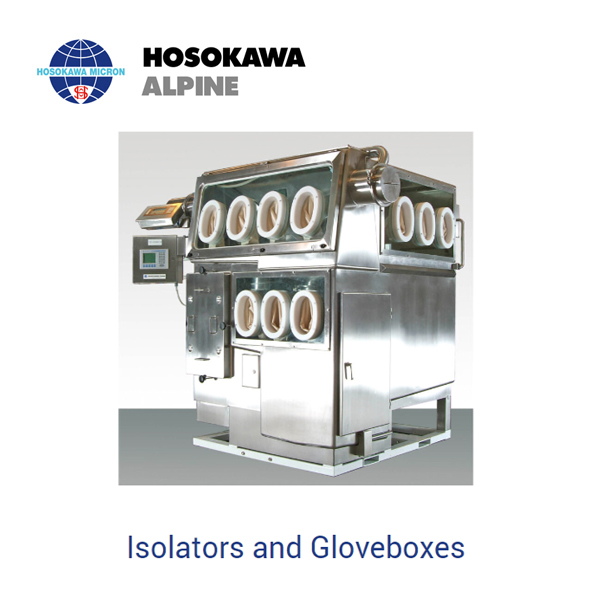

Isolators And Gloveboxes

Hosokawa Micron’s isolators and gloveboxes are uniquely designed for each customer depending on their very specific requirements and can vary widely in size, complexity, specification and functionality. Our team of containment experts is here to offer advice and guidance about the best containment solution for your needs and to create high-performance glovebox and isolator systems that are safe, robust and will provide decades of reliable service.In addition to the standard features you would expect to find as part of a static isolator or glovebox, we can also integrate additional functionality and features to meet and exceed the latest industry standards.

Also Suitable for:

- Pharmaceuticals

- Chemicals

Features:

- handles and processes hazardous, toxic and potent materials

- Excellent build quality and performance levels

- Energy-efficient using the latest technology

- Available in a range of sizes and configurations

- Equipment OELs down to 10ng/m3 (8-hour TWA)

- ISO Class I nuclear gloveboxes with leak tightness to less than 0.05% volume per hour

- cGMP, GAMP and FDA-compliant isolators and sterile isolators for aseptic product handling

- ATEX compliant integrated nitrogen purge systems

- CE/UKCA and UL-certified equipment

- Integrated CIP and WIP systems

- Safe change HEPA filtration systems

- Unidirectional air flow systems

- Viable and non-viable particle monitoring

- Integrated VHP sterilisation available

- Negative or positive internal pressure control options

- Push button or HMI operator control interfaces available

- Integration with customer DCS

- Tailor-made equipment and integrated process systems

- Manual or automated handling and processing solutions available

- Full testing and validation service, including IQ/OQ execution, OEL testing and filter DOP testing

- Document packs for certification and materials traceability

- Full operating manuals supplied

- Site installation and commissioning service

Optional Features

- Integrated CIP/WIP system

- ATEX compliant integrated nitrogen purge system

- Unidirectional flow filtration (Sterile Isolator)

- Viable and non-viable particle monitoring (Sterile Isolator)

- Integrated VHP sterilisation (Sterile Isolator)

- Negative or positive internal pressure control options